Silicone rubber products are based on methyl vinyl silicone rubber, adding various fillers (reinforcing agents, heat-resistant agents, modifiers, etc.) Bonding and other production processes are made. Silicone rubber products are activities in which silicone and rubber are the main raw materials to produce various silicone rubber products. Silicone rubber products are closely related to people’s lives. Remote controls, keyboards, pos machines, scanners, mobile phones, electronic dictionaries, mobile phone sets, etc. Silicone rubber products are related.

Features:

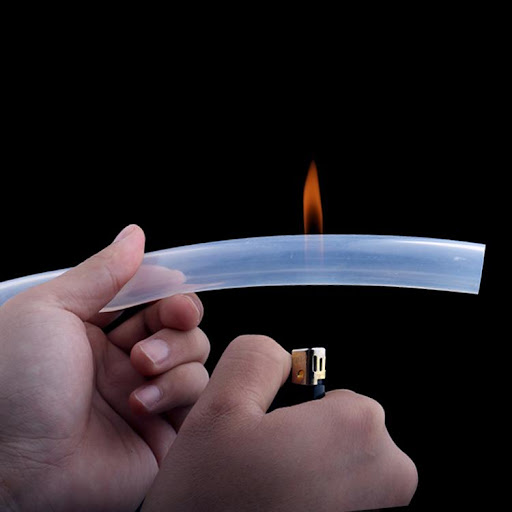

(1) High and low temperature resistance: It can be used for a long time at 200°C, and still elastic at -60°C.

(2) Electrical conductive properties: The conductive silicone rubber sheet are excellent, especially the dielectric properties at high temperatures are much higher than those of ordinary organic rubbers, and the dielectric strength is almost unaffected by temperature in the range of 20-200 °C.

(3) Excellent weather resistance, ozone resistance and ultraviolet radiation resistance, and no cracking occurs when used outdoors for a long time. It is generally believed that silicone rubber can be used outdoors for more than 20 years.

(4) Excellent high temperature compression set.

(5) With the advantages of good processing performance and easy molding, various products can be produced by extrusion hot air vulcanization molding, mold addition molding, and extension molding.

Silicone rubber product application:

Due to its excellent comprehensive performance and good technical and economic effects, silicone rubber products have been widely used in various fields of aviation, aerospace, atomic energy, electrical appliances, electronics, instruments, automobiles, machinery, metallurgy, chemical industry, medical and health care, and daily life. application. Silicone rubber products are biocompatible materials, so qualified food grade silicone sheets can be used as artificial organs, and can be used in the beauty industry and physiotherapy industry.

Common Questions about Silicone Rubber Products:

-

Why does the silicone rubber mold have a small number of overturns?

In the process of making the mold, too much silicone oil is added, and the silicone oil destroys the molecular weight of the silicone, so the mold will be turned over less frequently and not durable. If it is said that small products with complex patterns are used to open the mold with high hardness silica gel, there will be a phenomenon that the number of mold turning is less, because the time when the silica gel is too hard will be very brittle and easy to break. On the contrary, if you make a building product and use silicone with a low hardness to make a mold, the result will also be unsatisfactory. Because the silicone is too soft, its tensile force and tear strength will be reduced, and the resulting mold will be deformed, so the number of overturning will be reduced. The quality of the mold silicone itself is very good. There is no good or bad silicone, only suitable and unsuitable. This situation will not occur if the mold is made of silica gel that is suitable for the hardness of the product.

-

Why does the silicone rubber mold burn out?

Because unsaturated resin and resin products are added with peroxide curing agent, they will generate a lot of heat when they react with the resin. Generally, the curing time of resin is 3 minutes, so it is necessary to release the mold as soon as possible after 3 minutes to prevent the silicone mold from not being damaged and the phenomenon of mold burning occurs.

-

Why does the mold silicone rubber appear dry on the outside and wet inside?

Mold silica gel is a condensation type silica gel, which is solidified by absorbing moisture in the air. During the process of making silica gel, the moisture is evaporated to dryness without adding appropriate amount of moisture, which will cause surface dryness. phenomenon of non-working. Solution: This phenomenon is not a product quality problem, but because the water is not controlled, the storage period of the silica gel is increased, and the shelf life is long, and some phenomena will occur. As long as the silica gel is used, an appropriate amount of 0.05% water is added and stirred evenly. Some situations can be resolved.

-

Why does the mold silicone rubber have poor tension?

In the process of making the mold, in order to reduce the viscosity of the silica gel and make the silica gel easy to operate, a large amount of silicone oil is added to the silica gel, which will make the silica gel very soft, resulting in poor tensile strength and reduced tear strength. The phenomenon of poor tensile force, resulting in the phenomenon that the mold is not durable, the service life is short, and the number of mold overturns is small.

-

Why does the mold silicone rubber appear oily?

The mold silicone itself will not emit oil. The oil is caused by the addition of composite silicone oil (complex of silicone oil and white mineral oil) during the operation, because white mineral oil is a petrochemical product, not silicone oil.

-

Why is the mold not resistant to acid and alkali, and not resistant to aging?

In the process of making silicone molds, it is recommended that customers do not add any silicone oil. If necessary, the amount of silicone oil added should not exceed 5% to 10%. Because the addition of too much silicone oil will destroy the molecular weight of the silica gel, the resulting mold will not be resistant to acid and alkali, and is not resistant to aging.